The product

The unprotected steel, exposed to the atmosphere, is subject to corrosion. The cost of corrosion is rated at about 4% of the gross domestic product of an industrial country. To avoid corrosion damage, steel structures must be protected from corrosion throughout the life time required by the structure.

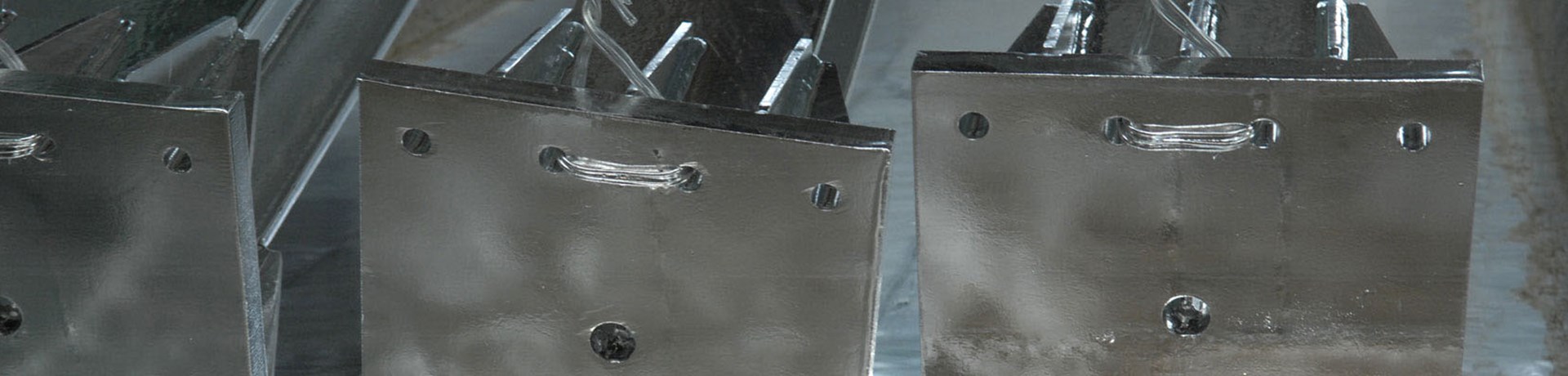

Hot-dip galvanizing offers an excellent solution to the problem of corrosion for metal surface. The layer of the molten zinc reacts with the metal surface of the steel fabrication becoming one with it.

Hot-dip galvanizing gives protection to the steel in two complementary ways: a zinc barrier effect which interposes and isolates the surface from the action of oxygen and oxidizers; and a cathode protection, an electrochemical phenomenon which prevents steel oxidation. In case of scratches which expose the underlying surface to the external agents, the surrounding zinc layer will corrode safeguarding the steel of the steel fabrication. The zinc coating can be performed on each element in steel: either on the structures of a building or on furniture and smaller items.

In order to obtain a good hot-dip galvanization it is necessary the collaboration between the designer, the manufacturer and the galvanizer.

Download the manual "Best Practices for Hot Dip Galvanizing"